Pinwheel arithmometers

Early arithmometers were built by clockmakers in XVII century. One of the first was Schickard arithmometer, built in 1623, destroyed in fire 1624, half year after finishing its construction. More known arithmometers were Pascal's Pascalina (there was a moment Poland had half of world's computers: two Pascalinas!), smaller device invented by S. Morland and Leibnitz multiplying machine, which was more similar to modern arithmometers.

|

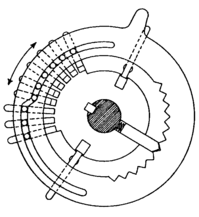

In 1709 Giovanni Poleni built first arithmometer with

pinwheel mechanism to select numbers. In 1727 Antonin Braun from Austria

modified Poleni's design to use crank instead of weight mechanism (like

in old clocks) which made arithmometer smaller. After Braun's design

demonstration, Poleni destroyed (or was forced to destroy - as

can be read in older, especially German documents) most of his machines. Later many arithmometers used sliding wheel with stepping protrusions, a completely different mechanism. |

G. Polleni. |

Revolution came in 1890, when W. Th. Odhner, Swedish engineer working in Russia, started to manufacture pinwheel arithmometers en masse. These arithmometers, invented 15 years earlier, were much cheaper and simpler, so they became available for offices or bureaus. "Odhner arithmometers" or "Brunsviga" arithmometers (clone) were manufactured in many factories to late 1970s. You can read more about Odhner arithmometers reading about Feliks arithmometer, as it's Odhner's clone.

Feliks arithmometer (Феликс)

After Soviet revolution in 1917 Odhner came back to Sweden, where he

opened another factory. Nationalized factory in St. Petersburg was not

manufacturing much until 1924, when it was moved and recommended by

Feliks Dzerzhinsky, head of WChK (much later KGB) as calculating

machines were essential in economy (well, especially for bureaucracy

fanatics like Dzerzhinsky).

In late 1940s factory was moved to Kursk (during WWII all factories were

moved to the east) and renamed to "Счетмаш" (Schyotmash) and they still

manufactured arithmometers. This arithmometer was probably manufactured

in early 1960s.

Unfortunately these arithmometers were manufactured using very low

quality process. Because steel was needed for other purposes and brass

was precious for industrial installations, they used worst quality

zinc-based alloy to make pinwheel casings. This alloy is very brittle

and now it's quite common in "Felix" that they have shattered inside of

pinwheels - slider cannot be moved by any force (well, if you try with

bigger tools you can only shatter a whole shaft). In fact this

alloy should have never been mechanized, it was

casting alloy. Any tries to mechanize it caused problems with breakings

(inclusion-based or notch effect) and making cool down faster (to

manufacture more parts in short time) made more inclusions in structure.

|

|

|

| General view | These butterfly nut is for setting 0 | Numbers set to counter 1 |

|

|

|

| Protective cover | Name engraved in case | Rotations count and serial no |

|

|

|

| Secondary counter | Carrier gears detail |

Triumphator CRN2

Triumphator is an old German brand of arithmometers.

Factory was established as "Lepiziger Rohrenwerke GmbH" in 1900 in

Lepizig. In 1909 they started to use Triumphator brand and renamed

factory to "Triumphator Rechenmaschinenfabrik GmbH". After 1948 they

moved and renamed to "VEB Triumphator-Werk Rechenmaschinenfabrik Molkau/Lepizig",

and operated under East German government.

They probably stopped manufacturing arithmometers in 1965.

Triumphator CRN2 is one of their last arithmometers, as CRN1 was

manufactured 1953-1959. It is more rigid than Soviet "Feliks" and use

better alloys. It has also a few features not commonly seen in typical

arithmometers.

- A lever on the crank shaft changes shaft's direction without changing

direction of spinning.

- Two little levers on the right side of bottom counters can be used to

exclude one of 2 counters from cleaning by pushing zero lever.

- R button below these little levers - if pushed and counter III is cleared,

number from counter III will be transferred to top counter. You should

clear top counter before.

- Shifting bottom 2 counters can be realized using push lever in the

middle (freely) or with two-sided lever near crank shaft (stepping).

Some photos of other unit:

http://public.beuth-hochschule.de/hamann/triumph/cnx/index2r.html

|

|

|

| General view | Setting number in counter 1 | Counter 3 |

|

|

|

| Direction switch | Marking | Serial no and type |

|

||

| Manufacturer's sticker |

Schyotmash WK1 (Счетмаш ВК-1)

Arithmometers with keys were developed since mid-XIX

century, but keyboard mechanism was complicated, expensive and required

additional actions: after pressing key it was needed to pull some

lever to make ratchet or gear rotate other gears to set a number. You

can see one of these mechanisms

here.

I don't know who invented arithmometer with combined action, but some

very early models with similar technology were built in 1930s. Combined

action means: Pressing a key causes distance delimiter to lock in digit

(usually made in a form of two "segments") instantly, pressing it

deeper makes gear move with delimiter, and, usually during key release,

pinwheel block is shifted by 1 allowing new number to be introduced.

Arithmometers with keyboards were manufactured in parallel with Feliks

units - since 1960s, but they stopped making them long after Feliks - in

1980s.

It was still poor quality instrument, made of bad alloys and with poorly

fitted mechanical parts. Typical problem, except many different jams, is

with zero-setting ratchet, you have to manually set it to zero of gear

with cut-through. Do not remove zeroing shaft because you won't put it

back easily (if you put it back and some wheels don't go zero... good

that you placed it back in wheels set). The main idea of operation is (if you see it you'll

understand it better):

1. You pull the lever, ratchet rotates zeroing gear.

2. Zeroing gear is mounted on a spring, it's side is not flat, but has

protrusion, near this side there's a circular ramp making gear go

horizontally towards zeroing shaft (with spring! it does NOT put shaft

in, only spins it!) as it rotates.

3. As ratchet rotates gear, gear is going horizontally towards shaft,

ratchet finally meets cut-through.

4. Then ratchet comes back through cut-through, without rotating gear,

lever is released.

5. Gear without ratchet springs back into its horizontal position ready

for another zeroing.

If there's a problem with upper zeroing mechanism, horizontal position

of ratchet should be checked. If ratchet moves horizontally with lever,

parts are worn out.

If it works but needs much force, just use WD40, CX80 or similar grease

in spray, use it a lot and try to lubricate all mechanism by rotating

shaft.

|

|

|

| General view | Counters | Keyboard |

|

|

|

| Manufacturer's stamp on the bottom | Carrier moving mechanism | Cover removed |

|

|

|

|

| Pinwheels visible from rear | Top view |

Predom-Mesko KR-13

This unit is very similar to Soviet one, but it has

better mechanism, works smoothly and has "look and feel" copied from

Facit units. Inside it's much like WK1. It was manufactured in Mesko

Skarzysko-Kamienna in Poland, (these times Mesko was making weaponry,

sewing machines, arithmometers and lawnmowers were secondary products)

under Predom Mesko brand (Predom was a cooperation of household devices

manufacturers). These arithmometers were manufactured since early 70s,

this one is labelled Mesko, not Predom-Mesko as these from late 70s and

80s, it's quite old unit.

This unit comes from University of Agriculture, I took it from their

rubbish bin in early 2000s.

|

|

|

| General view | Levers | Keyboard |

|

|

|

| Counters | Manufacturer sticker | Manufacturer's plate on the bottom |