Some of the devs at work were struggling to get their software talking

to a Dallas 1-wire device. I remember doing 1-wire comms back in

the 1990s, but I hadn't done any 1-wire lately and all of my old code

was for processors I no longer had running. But I had a weekend

free, so I figured I'd pull some old 1-wire devices out of the junk bin

and write a bit o' code...

The 1-wire protocol

The Dallas (now Maxim) 1-wire protocol uses a ground wire and a

single wire that is both Vdd and data. This data line is treated

by the master and slave devices as an open-collector line. By

convention, master and slave let the line float high, but pull the line

low to alert the other device or to drive data on the line. The

data line must include a 4.7 kohm resistor to +5 VDC, so the data line

idles at a logic high. Note that there are conditions where you

might want to switch in a stronger pullup temporarily; if your device

requires such a stronger pullup, it will be called out in the datasheet.

The protocol requires that both master and slave follow a prescribed

sequence of operations and adhere to timing constraints. Full

details on protocol and timing can be found in any of the Maxim/Dallas

data sheets for the 1-wire devices.

The master must drive the data line in open-drain mode; the master

CANNOT have internal pullups or pulldowns activated!

Interactions between master and slave (device) always begin with the

master pulling the data line low for at least 480 usecs; this is called

a reset or initialization pulse. The master releases the data

line so the pullup resistor can pull the line high. The device

must then respond by pulling the data line low for 60 to 240 usecs;

this is called a presence pulse. After sending the presence

pulse, the device releases the data line so it can return high.

After the master sees the presence pulse, the master is free to send a

command byte to the device. Details at this point vary based on

the number and type of devices connected. I don't want to get

bogged down in the details of multi-drop 1-wire networks, so I'll refer

you to the Maxim literature. For this demo, I'm going to focus on

a single 1-wire device hooked to the master.

The demo setup

I had a DS1820 temperature sensor in my junk box, so that is the device

I used. The DS1820 datasheet on the Maxim website contains all

the timing and handshaking info you need to get the device talking to

your micro.

For the "micro", I chose to use an STMicros STM32F4 Discovery

board. Yes, it is overkill, but it's cheap, kind of hobbyist

friendly, and I had one laying around.

I chose to use port pin PC1 for my 1-wire data line. I tied a 3.9

kohm resistor between +5 VDC on the Disco board and PC1. I then

connected up a DS1820 by wiring its GND pin to GND on the Disco board,

its Vdd pin to +5 VDC on the Disco board, and its DQ (data) line to PC1.

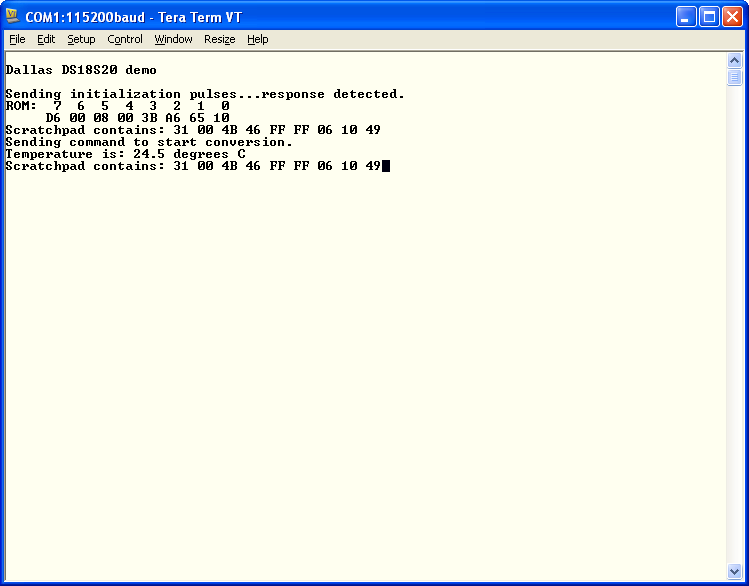

Finally, I brought out PD8 and PD9 from the Disco board to an RS-232

level shifter, so I could use TeraTerm to check the results of my

program.

The code

The code for making all of this work with the DS1820 is pretty

straightforward. I've added support for features such as reading

the device's ROM, which contains the family code and serial number, as

well as the scratchpad. The scratchpad is a nine-byte block of

RAM that contains the latest conversion information as well as some

alarm information.

Sending 1s and 0s from the master in the 1-wire protocol is

simple. The master marks the start of a bit by pulling the data

line low. If the bit to send is a 1, the master pulls the data

line high between 1 and 15 usecs later. If the bit to send is a

0, the master keeps the data line low. Between 60 and 120 usecs

after the start of the bit, the master must ensure the data line is

again pulled high. This marks the end of the bit time.

Obviously, if the master just sent a 1, the line is already high at the

end of this bit time.

This operation is performed a total of eight times to send a single

byte. Note that bytes are sent LSB first.

Reading 1s and 0s from the slave is very similar. Again, the

master marks the start of a bit by pulling the data line low. The

master waits about 15 usecs, then releases the line and changes the

data line to an input. About 15 usecs later, the master reads the

state of the data line; a high means the slave sent a 1, and a low

means the slave sent a 0. The master waits an additional 35 usecs

or so before repeating the process for the next bit, if needed.

Again, this operation is performed a total of eight times to read a

single byte. As before, bytes are sent LSB first.

Commands from the master to the slave follow a set sequence:

- Send the initialization pulse

- Send a command that selects a particular device or all devices on

the network

- Send a command plus data OR receive data from the

device

- (Optionally) Read data from the device

For example, let's say I want to tell the device to start a temperature

conversion. That consists of the following steps:

- Send the initialization pulse

- Send a SKIP_ROM command

- Send a CONVERT_TEMP command

In this case, I "selected" the device by sending a SKIP_ROM

command. This tells all 1-wire devices on the network that

everyone is supposed to pay attention. Since there is only one

device on my network, the DS1820 is selected. The CONVERT_TEMP

command tells the selected device to begin a termpature

conversion. Note that a temperature conversion can take as long

as 750 msecs to complete.

To read the data from this conversion, I need to read the scratchpad,

then pull the data from bytes 0 and 1. This uses the following

steps:

- Send the initialization pulse

- Send a SKIP_ROM command

- Send a READ_SCRATCHPAD command

- Read nine bytes of data from the device

The above sequence works because I only have a single 1-wire device in

my network. If your network has multiple devices, you would need

to replace the SKIP_ROM command with a MATCH_ROM command, followed by

the 8-byte value for the device you want to select. Details for

collecting the ROM values from a network of devices can be found in the

Maxim literature.